Isikhwama sokuhlunga inayilonikanye nesikhwama sokuhlunga se-polyester siyehluka ngempahla, ukwakhiwa, kanye nokusebenza. Uhlobo ngalunye lunikeza izinzuzo eziyingqayizivele zokuhlunga uketshezi. Ukukhetha imidiya yokuhlunga isikhwama efanele kunomthelela ekusebenzeni kahle kokuhlunga kanye nemiphumela yesikhathi eside. Ukukhetha okulungile kusiza abasebenzisi ukuthi bathole umphumela ongcono kakhulu wohlelo lwabo lokusebenza oluthile. Imidiya yesihlungi sesikhwama ingathuthukisa ikhwalithi yomkhiqizo futhi icubungule ukwethembeka.

Siyini Isikhwama Sokuhlunga Inayiloni

Impahla Yesikhwama Sokuhlunga Inayiloni Nokwakha

Isikhwama sokuhlunga inayiloni sigqama ekuhlungeni izimboni ngenxa yezakhiwo zaso ezihlukile kanye nokwakhiwa. Abakhiqizi basebenzisa inayiloni monofilament mesh yekhwalithi ephezulu ukuze bakhe lezi zikhwama. Le mesh ifaka ukuluka okunembayo, okuqinisekisa usayizi wezimbotshana ezingaguquki kanye nokuhlunga okuthembekile. Ukwakhiwa kunikeza amandla amahle kakhulu nokuqina, okwenza isikhwama sesihlungi senayiloni silungele izindawo ezifunayo.

Ithebula elilandelayo ligqamisa izinto ezisemqoka ezihlukanisa izikhwama zesihlungi senayiloni kwezinye izinhlobo:

| Impahla | Imininingwane |

|---|---|

| Ukusetshenziswa Okufanelekile | Ukuhlunga Kwekhemikhali Yezomnotho Nemidiya Emaphakathi |

| Iyahambisana ne | Izincibilikisi ze-Organic, Amafutha, Ama-Microorganisms, Ama-alkali |

| Akuhambisani Ne | Ama-oxidizing agents, ama-Mineral Acids, ama-Inorganic Acids |

| Isilinganiso Sezinga lokushisa | 0-325°F |

| Isilinganiso seMicron | 5 µm ukuya ku-1,000 µm |

| Izinhlobo Zokwakha | Inayiloni Monofilament Mesh, Multifilament Mesh |

| Ezinye Izici Ezibalulekile | I-FDA-Ibanga Lokudla, Iyahlanzeka / Isebenziseka Kabusha, Amandla Aqine Kakhulu |

Izikhwama zokuhlunga inayiloni zimelana nokudabuka kanye nemihuzuko. Le khwalithi ibenza balungele ukuhlungwa kwezimboni lapho izimo ezinzima zivame ukwenzeka khona. Imeshi elukwe ngokuqinile ivumela amazinga okugeleza aphezulu, okuthuthukisa ukusebenza kahle ezinqubweni eziningi zokuhlunga zezimboni.

Izici Eziyinhloko Nezinzuzo

Izikhwama zokuhlunga inayiloni zinikeza izici ezimbalwa nezinzuzo ezizenza zibe yinketho ekhethwayo ekuhlungeni kwezimboni:

- Amandla aphakeme nokuqina asekela ukusetshenziswa kwesikhathi eside.

- Ukuhuzuka okuhle nokumelana nokugqoka kusiza ukugcina ukusebenza ezindaweni ezinzima.

- Ukuzinza okuhle kakhulu kwamakhemikhali nokushisa kuvumela ukusetshenziswa ekuchayekeni kwamakhemikhali okusesilinganisweni.

- Ukungqubuzana okuphansi kanye nezindawo ezibushelelezi zangaphezulu ziqinisekisa ukugeleza koketshezi okusebenzayo.

- Ukuhlukahluka kokusetshenziswa kuhlanganisa ukuhlanzwa kwamanzi, ukucutshungulwa kwamakhemikhali, nokukhiqizwa kwezimboni.

Abakhiqizi abafana ne-Precision Filtration bahlinzeka ngezikhwama zesihlungi senayiloni ngosayizi abajwayelekile nabangokwezifiso. Izinketho eziningi zokubeka uphawu, njengeRing Top nePlastiki Flange, zikhulisa ukuhambisana nezindlu ezahlukahlukene. Lezi zikhwama zingasetshenziswa kabusha, okusiza ukunciphisa izindleko ngokuhamba kwesikhathi.

Izikhwama zokuhlunga inayiloni nazo zihlangabezana nemithetho ye-FDA yezicelo zokudla neziphuzo. Bahlolwa kanzima ukuze bangene komoya namandla. Isikhwama ngasinye sivalwa ngasodwa emaphaketheni okuzivikela ukuze sigcine ubumsulwa futhi sinqande ukungcoliswa.

Ithiphu: Izikhwama zokuhlunga inayiloni zisebenza kahle kukho kokubili uketshezi olune-viscous oluphezulu kanye nemisebenzi evamile yokuhlunga yezimboni. Ukusebenziseka kabusha kwazo nokuhambisana nezindinganiso zebanga lokudla kuzenza zibe ukukhetha okuthembekile ezimbonini eziningi.

Iyini Isikhwama Sesihlungi Se-Polyester

Izinto kanye Nokwakhiwa Kwesikhwama Sesihlungi Se-Polyester

Izikhwama zokuhlunga ze-polyester zidlala indima ebalulekile ekuhlungeni kwezimboni. Abakhiqizi basebenzisa imicu ye-polyester ukuze benze lezi zikhwama, ezinikeza ibhalansi yamandla nokuguquguquka. Inqubo yokwakha ihilela ukwaluka noma ukusika imicu ye-polyester ibe indwangu ehlala isikhathi eside. Le ndlela ikhiqiza isikhwama sokuhlunga esingakwazi ukumelana namazinga aphezulu okugeleza nokucindezela ngaphandle kokudabula.

Izikhwama zokuhlunga ze-polyester zibonisa ukumelana okuhle kakhulu nokuhuzuka. Zigcina ukwakheka kwazo nobukhulu ngisho nalapho zichayeka emazingeni okushisa aphezulu. Izikhwama eziningi zokuhlunga ze-polyester zisebenza emazingeni okushisa afika ku-275°F, nama-surges amafushane afinyelela ku-300°F. Lezi zikhwama zisebenza kahle kakhulu ezimeni ezomile ezinama-asidi aphansi nama-alkali. Azinconywa ezindaweni ezinomswakama noma ezinomswakama kakhulu.

Ithebula elilandelayo lifingqa izici ezibalulekile zezikhwama zokuhlunga ze-polyester:

| Isici | Incazelo |

|---|---|

| Ukuhlunga Ngempumelelo | Okuphezulu, okusebenzayo ezinhlayiyeni ezinhle nothuli |

| Amandla Okuqina | Okuhle kakhulu, ukumelana nokudabula ngaphansi kwengcindezi |

| Ukumelana ne-Abrasion | Kuhle kakhulu, ukumelana nokugqokwa ekusetshenzisweni kwezimboni |

| Ukuzinza kweDimensional | Igcina isimo ngaphansi kokushisa, i-shrinkage ephansi |

| Ukuhlanza Kalula | Ingahlanzwa futhi isetshenziswe kabusha, kodwa ukuhlanza okuphindaphindiwe kungase kuthinte ukusebenza |

| Impilo Yesevisi | Isikhathi eside, kunciphisa isidingo sokushintshwa njalo |

| Isondlo | Kulula, kwehlisa izindleko zesondlo |

| Ukuguquguquka | Itholakala ngosayizi abaningi kanye nomumo |

| Ukusebenza Kwezindleko | Ithengeka uma iqhathaniswa nezinye izinto zokwakha |

Qaphela: Izikhwama zokuhlunga ze-polyester zitholakala kabanzi futhi zinikeza isisombululo esingabizi kakhulu ezimbonini eziningi.

Izici Eziyinhloko Nezinzuzo

Izikhwama zokuhlunga ze-polyester ziletha izici ezimbalwa ezibalulekile nezinzuzo. Isakhiwo sabo se-fiber esixekethile sandisa umthamo wokubamba ukungcola, okuthuthukisa ukusebenza kahle kokuhlunga. Lezi zikhwama zisebenzisa indlela yokuhlunga yezigaba ezimbili. Ukuhlunga okungaphezulu kuthatha izinhlayiya ezinkulu, kuyilapho ukuhlunga ukujula kubamba ukungcola kakhudlwana.

- Umthamo wokungcola othuthukisiwe usekela ukuhlunga okusebenzayo.

- Indlela yokuhlunga yezigaba ezimbili ithuthukisa ukukhishwa kwezinhlayiyana.

- Ukuqina ngaphansi kwengcindezi kuqinisekisa ukusebenza okungaguquki.

- Amandla e-tensile amahle kakhulu kanye nokumelana ne-oxidation kwandisa isikhathi sokuphila.

- Ukugcinwa okulula kusiza ukunciphisa izindleko zokusebenza.

Izikhwama zokuhlunga ze-polyester zenzelwe ukusetshenziswa okukodwa. Ukuhlanza nokusebenzisa kabusha lezi zikhwama kungalimaza impahla, okungase kuthinte ukusebenza kokuhlunga. Ukulimala kungase kubangele izimbotshana ezikhulisiwe noma ukuncipha, okuholela ekuxhumekeni ngokushesha noma kunciphise ukusebenza kahle.

Ithiphu: Izikhwama zokuhlunga ze-polyester zisebenza kahle kakhulu ezindaweni ezomile futhi zinikeza ukuhlunga okuthembekile kothuli, izinhlayiya ezinhle, kanye nezinhlelo zokusebenza zezimboni.

Umehluko Obalulekile Kumidiya Yesihlungi Sesikhwama

Ukuhlunga Ngempumelelo

Ukusebenza kahle kokuhlunga kudlala indima ebalulekile ekunqumeni ukusebenza kwemidiya yesihlungi sezikhwama. Izikhwama zokuhlunga ze-polyester zihamba phambili ekukhipheni izinhlayiya ezincane, zithatha izinhlayiya ezincane njenge-micron engu-1. Izikhwama zokuhlunga inayiloni zisebenza kahle ngezinhlayiya ezinkulu, zizenze zifanelekele izinhlelo zokusebenza ezingadingi ukuhlunga okuphezulu. Ithebula elilandelayo liqhathanisa ukusebenza kahle kokuhlunga kanye nobubanzi bezinhlayiyana zazo zombili izinto:

| Okubalulekile | Ukuhlunga Ngempumelelo | I-particle Size Range |

|---|---|---|

| I-polyester | Kuhle kakhulu (kuze kufike ku-1 micron) | 1 kuya ku-800 microns |

| Inayiloni | Kuhle (izinhlayiya ezinkulu) | 1 kuya ku-100 microns |

Izikhwama zokuhlunga ze-polyester ziletha ukusebenza kahle okuphezulu ekususeni izinhlayiya ezinhle, okubalulekile ezimbonini ezifuna imiphumela yokuhlunga. Izikhwama zokuhlunga inayiloni zinikeza ukusebenza kahle okuthembekile kwemisebenzi evamile yokuhlunga, ikakhulukazi uma umthamo wokubamba ukungcola udingeka. Zombili izinhlobo zemidiya yokuhlunga izikhwama zifaka isandla ekukhishweni kokungcola, kodwa i-polyester igqama ezinhlelweni ezidinga ukusebenza kahle kokuhlunga.

Izinga lokushisa kanye nokumelana namakhemikhali

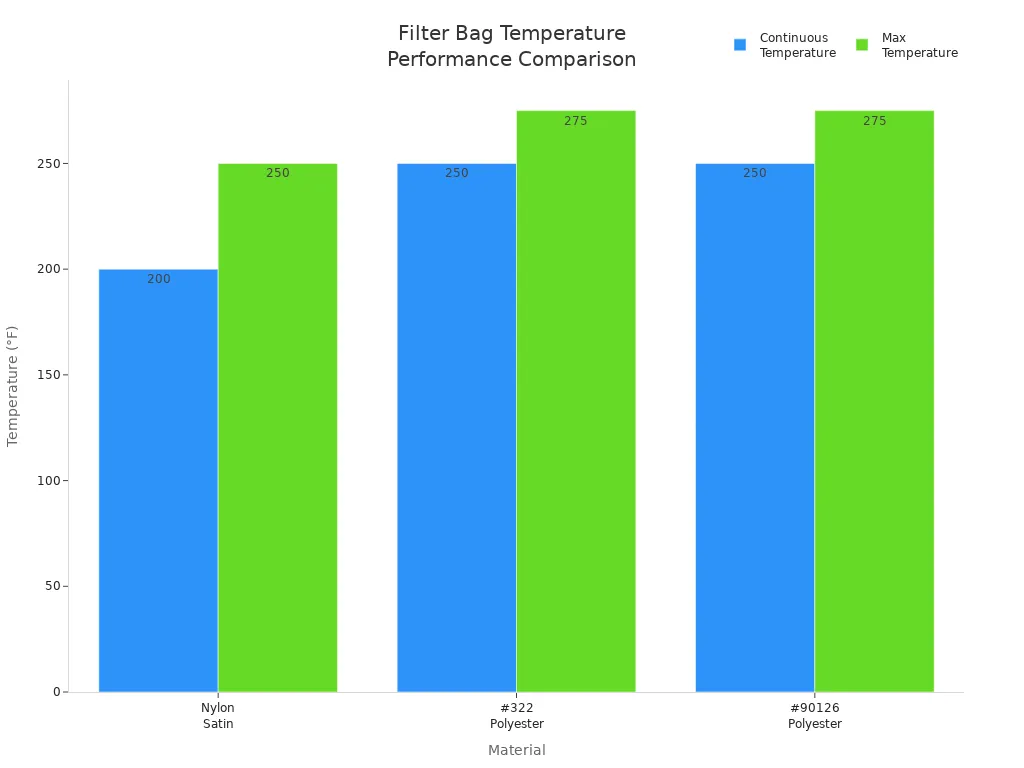

Izinga lokushisa nokuhambisana kwamakhemikhali yizici ezibalulekile lapho ukhetha imidiya yesihlungi sesikhwama. Izikhwama zesihlungi se-polyester zimelana namazinga okushisa aphezulu, zisebenza ngokuqhubekayo ku-250°F futhi zifinyelela ku-275°F. Izikhwama zokuhlunga inayiloni zisebenza kahle ngokufika ku-200°F ukuze zisetshenziswe ngokuqhubekayo, ezinobukhulu obungu-250°F. Ishadi elingezansi libonisa izilinganiso zezinga lokushisa zazo zombili izinto:

Izikhwama zokuhlunga ze-polyester zisebenza kahle kakhulu ekufakweni kokushisa okomile. Ezindaweni ezinomswakama, ikakhulukazi emazingeni okushisa aphakathi kuka-160°F no-210°F, i-polyester ingase ibe ne-hydrolysis, engenza indwangu ibe buthaka. Izikhwama zokuhlunga inayiloni zinikeza ukuhambisana okuqinile kwamakhemikhali nama-asidi abuthakathaka nama-alkali, kodwa azinconywa ngama-asidi aqinile noma ama-oxidizing agents. Izikhwama zokuhlunga ze-polyester zibonisa ukuhambisana okuhle kwamakhemikhali nama-asidi amaningi, okuwenza afanelekele uhla olubanzi lwezinhlelo zokusebenza zezimboni.

Ithiphu: Hlala ucabangela ukuhambisana kwamakhemikhali nezimfuneko zokushisa zenqubo yakho ngaphambi kokukhetha imidiya yesihlungi sezikhwama.

Ukuqina Nokuphila Isikhathi Eside

Ukuqina nempilo yesevisi eyandisiwe yizinto ezibalulekile zokucatshangelwa kwemidiya yesihlungi sezikhwama. Izikhwama zokuhlunga inayiloni zifaka amandla aphakeme anezikhala futhi zimelana nama-asidi abuthakathaka nama-alkali, anikela empilweni yawo yesevisi eyandisiwe. Izikhwama zokuhlunga ze-polyester nazo zinikeza ukumelana okuhle nokuguga, kodwa amandla azo anezikhala ngokuvamile aphansi kunenayiloni. Ithebula elingezansi ligqamisa izilinganiso zokuqina kwazo zombili izinto:

| Impahla | Inayiloni | I-polyester |

|---|---|---|

| Ukumelana nama-asidi abuthakathaka | Okuphakeme | Ukumelana |

| Ukumelana nama-asidi aqinile | Kuhlaselwe | Ukuhlasela kancane |

| Ukumelana nama-alkali abuthakathaka | Okuphakeme | Ukumelana |

| Ukumelana nama-alkali aqinile | Ukumelana | Kuhlaselwe |

| Amandla e-mesh | Kakhudlwana | Buthaka |

| Izinga lokushisa elincomekayo eliphezulu | 350°F | 250°F |

Izikhwama zokuhlunga inayiloni zisiza ukunciphisa izindleko zokusebenza ngokwandisa isikhathi phakathi kwezinguquko zokuhlunga. Ukuphila kwabo okude nokuhambisana kwamakhemikhali kubenza babe ukukhetha okuthandwayo ezinqubweni eziningi zezimboni. Ukugcinwa kahle kwemidiya yokuhlunga isikhwama kubalulekile ukuze kugwenywe ukulimala kwesistimu nokungasebenzi kahle. Izikhwama zokuhlunga ze-polyester nazo zinikeza ukuqina, kodwa ukuhlanzwa okuphindaphindiwe kungase kuthinte ukusebenza kahle nokusebenza kwazo.

Ukuqhathaniswa Kwezindleko

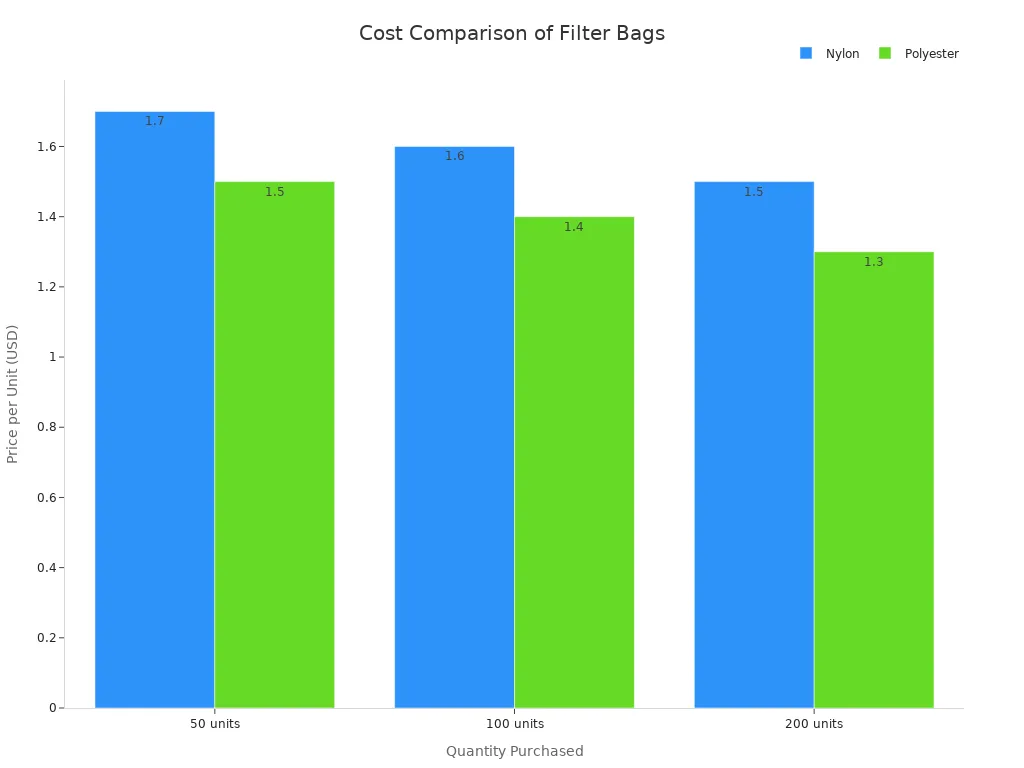

Izindleko ziyisici esibalulekile lapho kuhlolwa imidiya yesihlungi sezikhwama ukuze isetshenziswe ezimbonini. Izikhwama zokuhlunga ze-polyester ngokuvamile zinikeza inani eliphansi ngeyunithi ngayinye uma kuqhathaniswa nezikhwama zokuhlunga inayiloni, ikakhulukazi uma kuthengwa ngobuningi. Ithebula elingezansi libonisa umehluko wamanani amanani ahlukahlukene:

| Uhlobo Lwesikhwama Sokuhlunga | Ubuningi | Inani ngeyunithi ngayinye |

|---|---|---|

| Inayiloni | 50 | $1.700 |

| Inayiloni | 100 | $1.600 |

| Inayiloni | 200 | $1.500 |

| I-polyester | 50 | $1.500 |

| I-polyester | 100 | $1.400 |

| I-polyester | 200 | $1.300 |

Izikhwama zokuhlunga inayiloni zinikeza inani elihle kakhulu lemali ngenxa yokusebenza kwazo okuphezulu nokuqina. Banciphisa izidingo zokunakekela futhi basize ukunciphisa izindleko zokusebenza. Izikhwama zokuhlunga ze-polyester zinikeza ukufinyeleleka nokusebenza kahle, okuzenza zibe yisinqumo esidumile ezimbonini eziningi. Zombili izinhlobo zemidiya yokuhlunga izikhwama ziletha imiphumela yokuhlunga efanele, kodwa isinqumo sokugcina ngokuvamile sincike kusabelomali, isicelo, kanye nempilo yesevisi enwetshiwe.

Qaphela: Ukukhetha imidiya efanele yokuhlunga isikhwama kuhlanganisa ukulinganisa ukusebenza kahle kokuhlunga, ukuhambisana namakhemikhali, ukuqina, kanye nezindleko zokuzuza umphumela ongcono kakhulu wesistimu yakho yokuhlunga.

Ukufaneleka Kohlelo Nokusetshenziswa Kwesikhwama Sokuqoqwa Kwezithuli

Ukusetshenziswa Okungcono Kakhulu Kwezikhwama Zokuhlunga Inayiloni

Izikhwama zokuhlunga inayiloni zisebenzela izimboni eziningi ngenxa yamandla azo kanye nokuguquguquka. Izinkampani zisebenzisa imidiya yokuhlunga isikhwama eyenziwe ngenayiloni ekuhlungeni amanzi, ukuhlungwa komoya, nokuhlunga kwezimboni. Umkhakha wokudla neziphuzo uthembele ezikhwameni zokuhlunga inayiloni ukuze uhambisane nokuphepha. Ithebula elilandelayo libonisa izinhlelo zokusebenza ezivamile:

| Uhlobo Lohlelo Lokusebenza | Incazelo |

|---|---|

| Ukuhlunga Amanzi | Isusa ukungcola emithonjeni yamanzi. |

| Ukuhlunga komoya | Icupha izinhlayiya ezinhlelweni zokuhlanza umoya. |

| Ukuhlunga Kwezimboni | Ihlukanisa okuqinile kuketshezi ekukhiqizeni. |

| Ukuhlunga Ukudla Neziphuzo | Iqinisekisa ukuphepha ekucutshungulweni kokudla kanye nokukhiqizwa kweziphuzo. |

Izimboni ezifana nemithi, i-biotechnology, nokucubungula amakhemikhali zikhetha imidiya yesihlungi sezikhwama zenayiloni ngemisebenzi efana nokuvala inzalo nokucacisa. Izikhwama zokuhlunga inayiloni nazo zihamba phambili ezinhlelweni zezikhwama zokuhlunga uthuli, lapho ukumelana kwazo nokuhuzuka namandla okusebenza kunciphisa imvamisa yokushintshwa. Ukuhambisana kwawo kwamakhemikhali nama-alkali namakhemikhali emvelo kuwenza athembeke ezindaweni eziyinselele.

Izikhwama zokuhlunga inayiloni zinikeza ukusebenza kahle kokuhlunga okuphezulu, ukuqina, nokugcinwa kalula. Basusa amabhaktheriya nama-microorganisms, okubalulekile ekuphepheni kokudla.

Ukusetshenziswa Okungcono Kakhulu Kwezikhwama Zokuhlunga Ze-Polyester

Izikhwama zokuhlunga ze-polyester zinikeza ukuhlunga okusebenzayo ezimbonini zamakhemikhali, ezemithi, kanye ne-petrochemical. Izinkampani zisebenzisa le midiya yokuhlunga isikhwama ukuhlunga amakhemikhali anolaka, izinyibilikisi, namafutha. Ithebula elingezansi ligqamisa izinhlelo zokusebenza ezijwayelekile:

| Imboni | Incazelo Yohlelo Lokusebenza |

|---|---|

| Imboni Yamakhemikhali | Ukuhlunga amakhemikhali nezinyibilikisi. |

| Imboni Yezokwelapha | Ukuhlunga uketshezi lokuhlanzeka komkhiqizo. |

| Imboni Yokudla Neziphuzo | Ukuhlunga amafutha kanye nama-syrups. |

| Ukwelapha Amanzi | Ukuhlunga kwamanzi angcolile ukuze kukhishwe ukungcola. |

| Imboni ye-Petrochemical | Ukuhlunga imikhiqizo ye-petroleum namafutha. |

Imidiya yokuhlunga isikhwama se-polyester isebenza kahle ezindaweni ezomile futhi inikeza ukumelana ne-UV. Ihambisana nezimoto, i-aerospace, kanye nezicelo zokuhlanza amanzi angcolile. Izikhwama zokuhlunga ze-polyester zibamba izinhlayiya ezomile nothuli ngendlela efanele, okuzenza zibe yinketho ethandwayo ezinhlelweni eziningi zokuqoqa uthuli.

Ukukhetha Isikhwama Sesihlungi Esingakwesokudla

Ukukhetha imidiya yokuhlunga isikhwama esifanele kuncike ezintweni ezimbalwa. Abasebenzisi kufanele bacabangele izidingo zokuhlunga, izimo zemvelo, nezidingo zokunakekelwa. Ithebula elingezansi liqhathanisa izici zenayiloni ne-polyester:

| Isici | Izimpawu zenayiloni | Polyester Izici |

|---|---|---|

| Izidingo Zokuhlunga | Iphatha izinhlayiya eziqinile noma ezicijile | Iphatha kahle izinhlayiya ezomile nothuli |

| Izimo Zemvelo | Ukuqina okuphezulu, ukuchayeka kwamakhemikhali okumaphakathi | Ukuvikelwa okuhle komswakama, ukumelana ne-UV |

| Isondlo Nezindleko | Ingase idinge ukunakekelwa okukhethekile | Ihlala isikhathi eside ngokuhlanza okulula |

Ukukhetha imidiya efanele yokuhlunga isikhwama kuqinisekisa ukusebenza kahle nokonga kwezindleko. Izikhwama zokuhlunga inayiloni zifanelana nezindawo ezifunayo nezinqubo ezibucayi. Izikhwama zokuhlunga ze-polyester zisebenza kangcono ekuhlungeni okujwayelekile nokuqoqwa kothuli. Izinkampani kufanele zifanise imidiya yesihlungi sezikhwama nohlelo lwazo oluthile nendawo ukuze uthole imiphumela engcono kakhulu.

Ithiphu: Hlala uhlola izidingo zenqubo kanye nezimo zemvelo ngaphambi kokukhetha imidiya efanele yokuhlunga isikhwama.

Izikhwama zokuhlunga inayiloni ne-polyester ziyehluka ngokuphathekayo, ukuqina, nokusebenza kahle kokuhlunga. Inayiloni ifanela uketshezi lwe-viscous futhi ihlangabezana nezindinganiso ze-FDA zokuphepha kokudla. I-polyester isebenza kahle ekuhlungeni okujwayelekile koketshezi kanye nezindawo ezomile. Ochwepheshe bokuhlunga batusa ukucabangela lezi zindlela zokunquma:

| Imibandela | Incazelo |

|---|---|

| Izinhlayiya izici | Usayizi nohlobo lwezinhlayiya okufanele zikhishwe |

| Izimo Zenqubo | Izinga lokugeleza, ingcindezi, nezinga lokushisa |

| Hlunga Izinhlobo Zemidiya | Ukuhambisana okubalulekile nohlelo lokusebenza |

| Hlunga Izindlu | Ukufaneleka kwezidingo ezithile zesistimu |

Ukukhetha isikhwama sokuhlunga esifanele kusho ukuhlola izidingo zohlelo lokusebenza, indawo ezungezile, kanye nesabelomali. Ikhwalithi yomkhiqizo nokuhambisana nokulawula kuqinisekisa ukuhlunga okuphephile nokusebenzayo.

FAQ

Uyini umehluko omkhulu phakathi kwezikhwama zokuhlunga zenayiloni ne-polyester?

Izikhwama zokuhlunga inayiloni zisebenzisa i-monofilament mesh ukuze zibe namandla nokuqina. Izikhwama zokuhlunga ze-polyester zisebenzisa imicu elukiwe noma ethintekile ukuze kube lula ukuguquguquka kanye nokuhlunga izinhlayiyana ezinhle. Impahla ngayinye ifanelana nezidingo zokuhlunga ezahlukene.

Ingabe izikhwama zokuhlunga zenayiloni zingasetshenziswa kabusha?

Yebo. Izikhwama zokuhlunga inayiloni zinikeza ukusebenziseka kabusha ngenxa yemeshi yazo eqinile nokuhlanza kalula. Izimboni eziningi zikhetha inayiloni ukonga izindleko kanye nokusetshenziswa isikhathi eside.

Ingabe izikhwama zokuhlunga ze-polyester ziphephile ukusetshenziswa kokudla nesiphuzo?

Izikhwama zokuhlunga ze-polyester zingasetshenziswa ekucubunguleni ukudla nesiphuzo. Abasebenzisi kufanele bahlole ukuthobela kwe-FDA ngaphambi kokukhetha umkhiqizo othile walezi zinhlelo zokusebenza.

Isiphi isikhwama sokuhlunga esisebenza kangcono emazingeni okushisa aphezulu?

Izikhwama zokuhlunga ze-polyester zisebenza kahle ezindaweni ezinezinga lokushisa eliphezulu. Zimelana nokushisa okuqhubekayo kufika ku-250°F. Izikhwama zokuhlunga inayiloni nazo zimelana nokushisa kodwa zifanelana nezinga lokushisa elimaphakathi.

Ngisikhetha kanjani isikhwama sokuhlunga esilungile sohlelo lwami lokusebenza?

Ithiphu: Cabangela uhlobo loketshezi, izinga lokuhlunga elidingekayo, ukuhambisana kwamakhemikhali, nezinga lokushisa. Buyekeza ukucaciswa komkhiqizo futhi uxhumane nochwepheshe bokuhlunga ukuze uthole imiphumela ehamba phambili.

Isikhathi sokuthumela: Dec-05-2025